Flexible core technology

The future of visual inspection is digital, AI-based and customized.

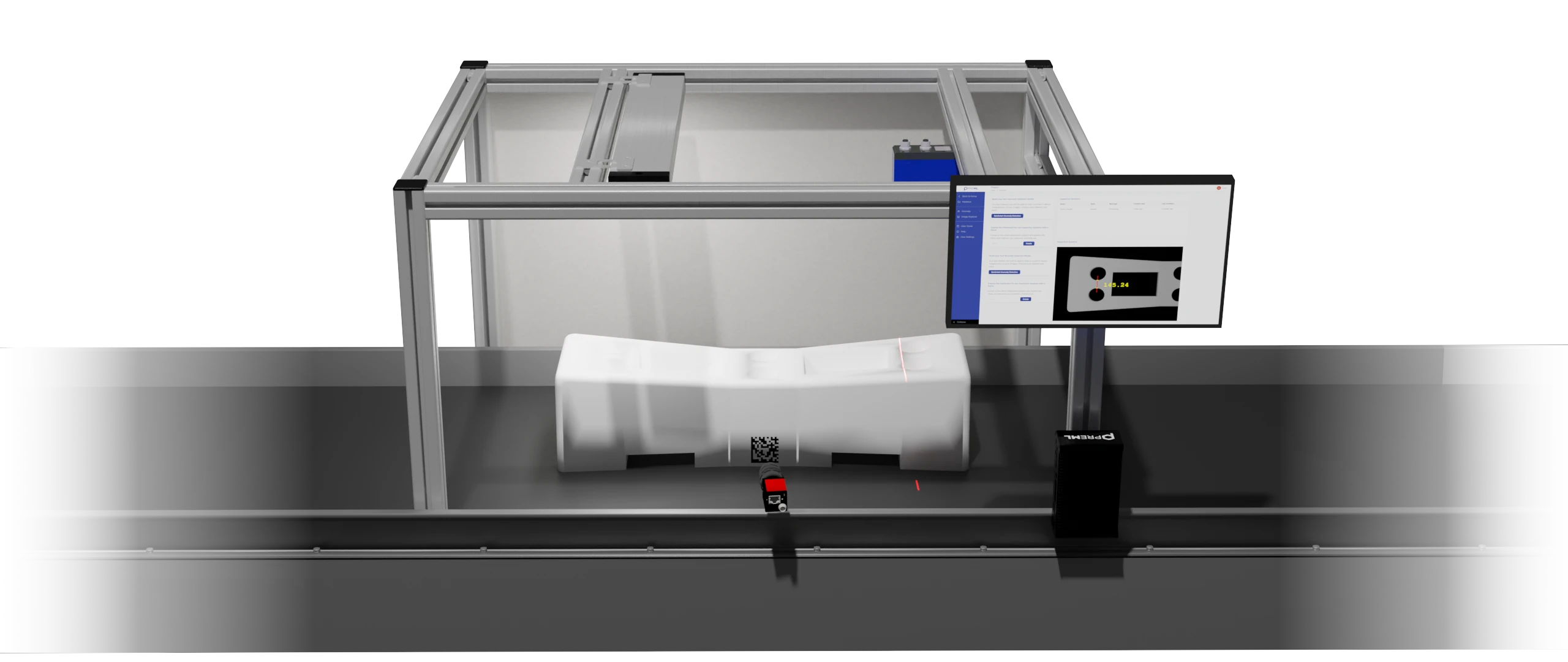

Modular components of your system

Your product, production and quality requirements are unique. We adapt our components to your specific setting.

CVC Inspect

We use artificial intelligence to identify and qualify defective components on image data in real time.

- Image Aquisation

- Image Processing

- Object Detection

Anomaly Detection

- Error Classification

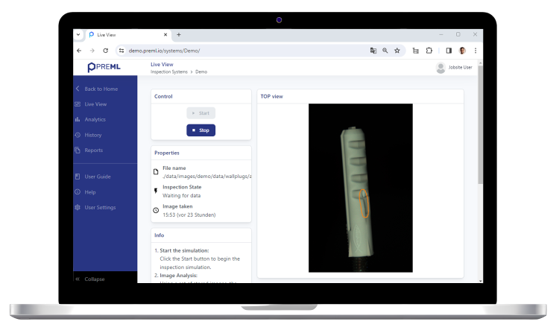

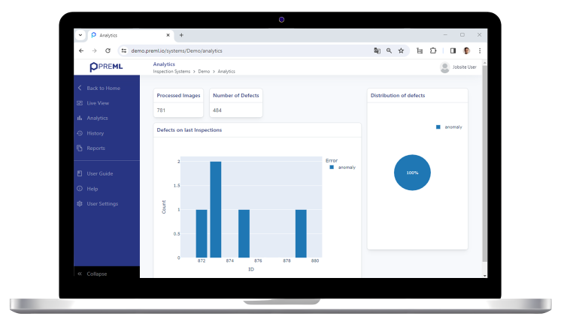

CVC Control

Through our live view and dashboard analytics, you can remotely access quality reports and indicators.

Real-time visualisation

Statistics

Documentation

Reports

And many more features

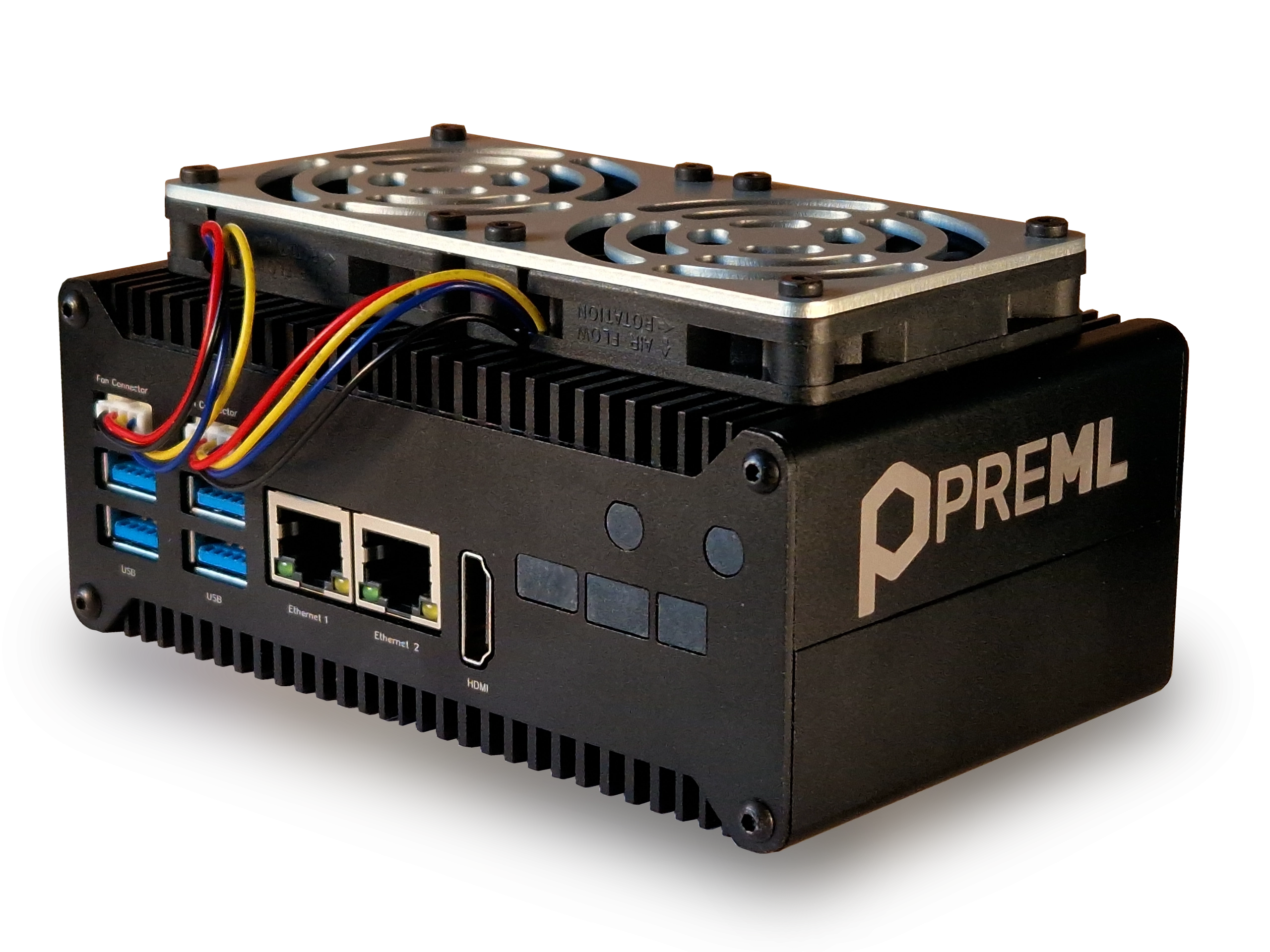

Power Edge

Our Edge Device ensures independent high performance despite shocks and contamination.

NVIDIA hardware

IP-housing

Customized ports

Regular updates

1 year warranty

Industrial Cameras

We select cameras according to your use case and environment.

Customer Requests

We help you to customize our system according to your requirements and needs.

Lighting & Installation

We help you to install your new visual inspection system.

Benefits

Gapless control & documentation

Reduce costs

Keep employees away from danger

Enable high cycle time

Always follow quality metrics

Traceability

From an idea to a ready-to-use system

Our onboarding process minimizes your risk and has proven itself in practice.

1. Feasibility Check

Together we discuss and review your application. A positive result consists of technical feasibility, economic efficiency and the achievement of your specific quality requirements. We offer this item free of charge.

2. Proof of Concept

Together we create an image data set for your application. The image data is annotated, analyzed and processed with our AI algorithms. Our goal is to identify pitfalls and make predictions about subsequent performance.

3. Implementation Phase

We install the hardware in your production environment. We collect real data, train our models and improve our initial model until we reach the maximum. This phase ends with a factory acceptance test.

4. Roll-out

Whether you bought our system to reduce costs or to generate new business, from now on you’ve got it. Through our subscription plans, you will benefit from continuous updates and support. Don’t worry you are in good hands, feel free to contact us for reference customers.