Fast customization

for highly individualized inspection systems designed to handle a diverse range of tasks.

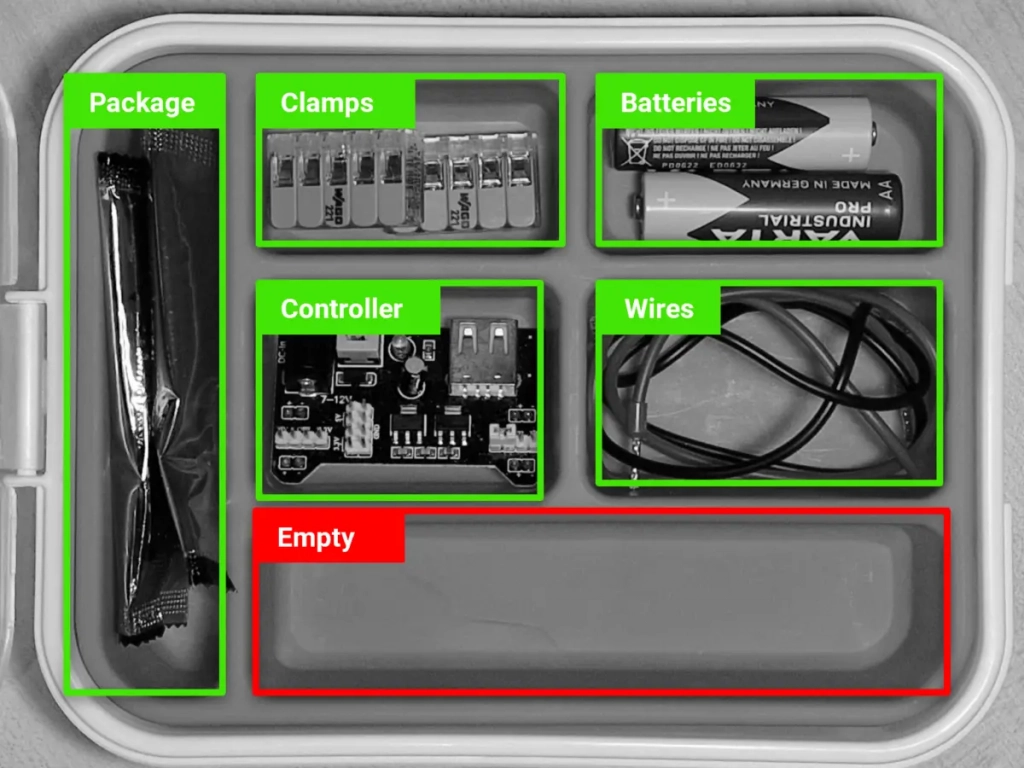

Completeness Check

Inspects: Assembly Parts

This solution ensures the completeness of assembly sets. This real-time system leverages advanced AI algorithms to detect missing parts during the assembly process. It is user-friendly, allowing factory personnel to make adjustments easily and independently.

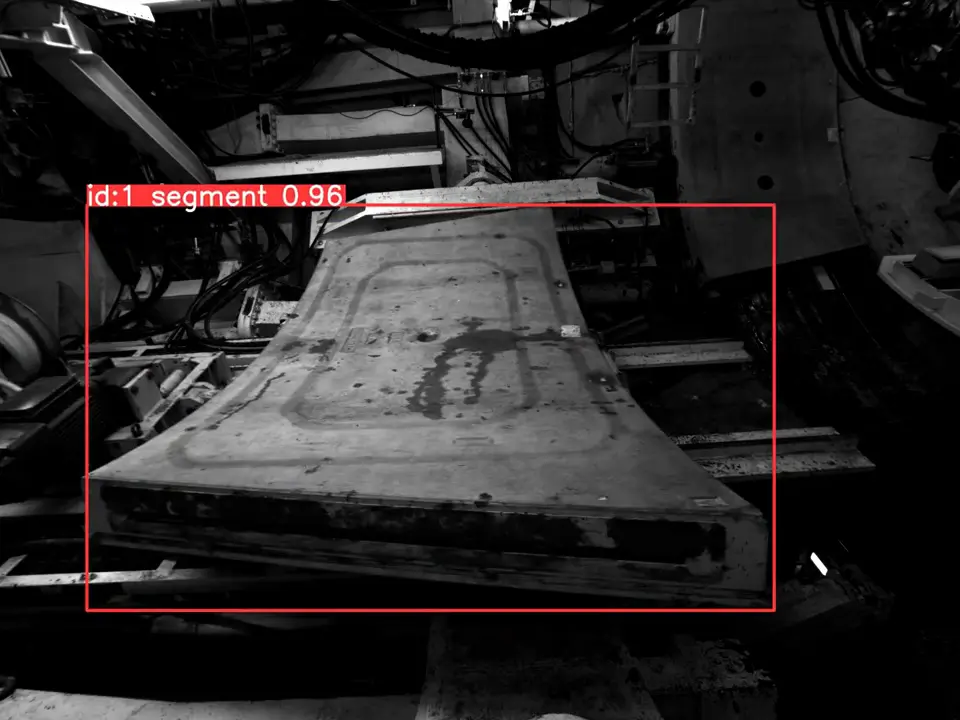

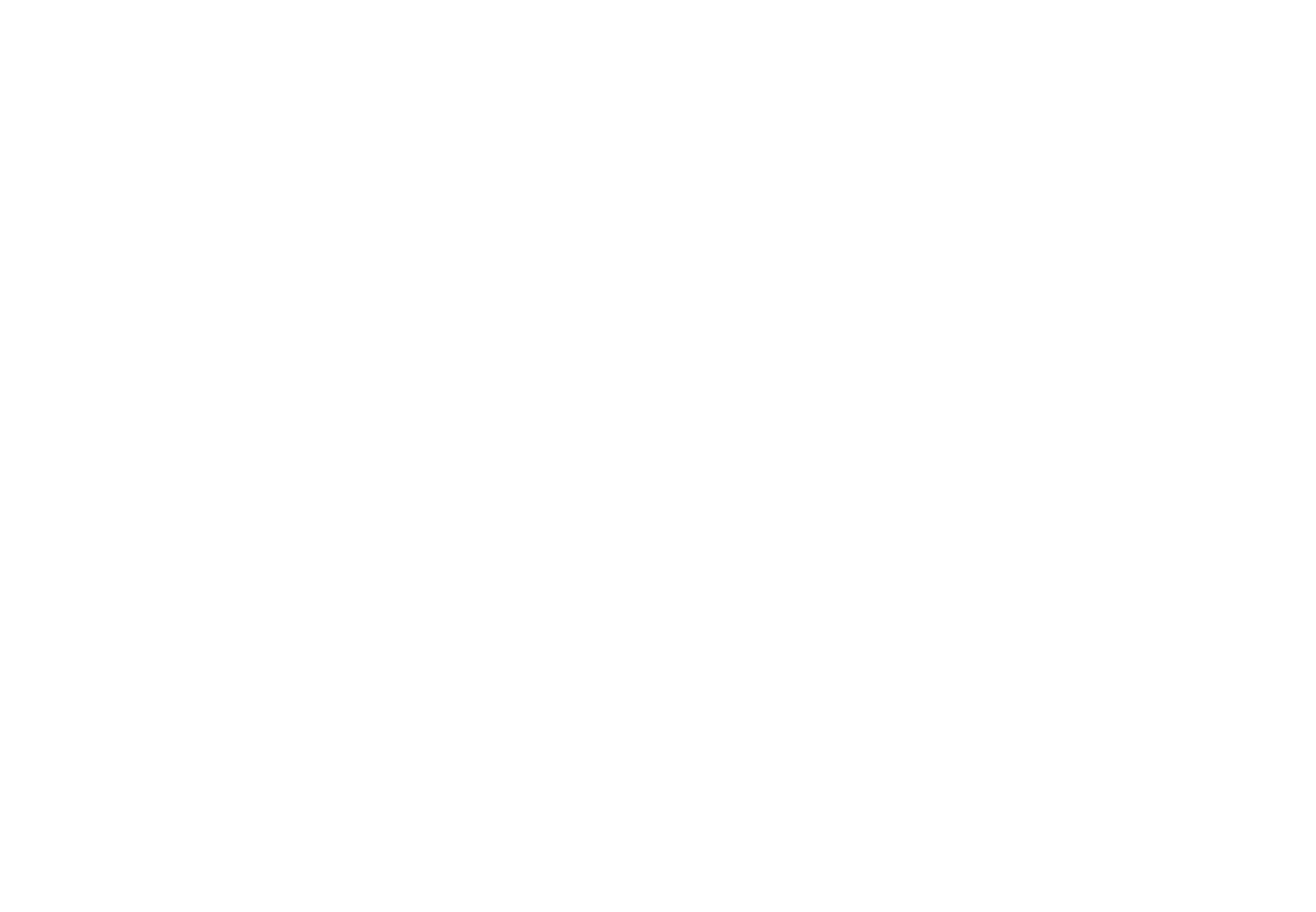

Concrete Crack Detection

Inspects: Tunnel segments

The market leader uses our software in its premium tunnel boring machines for final quality inspections of tunnel segments underground. Our system identifies each segment in the images and calculates its position in 3D space, allowing us to isolate each side and inspect it for damage or missing parts.

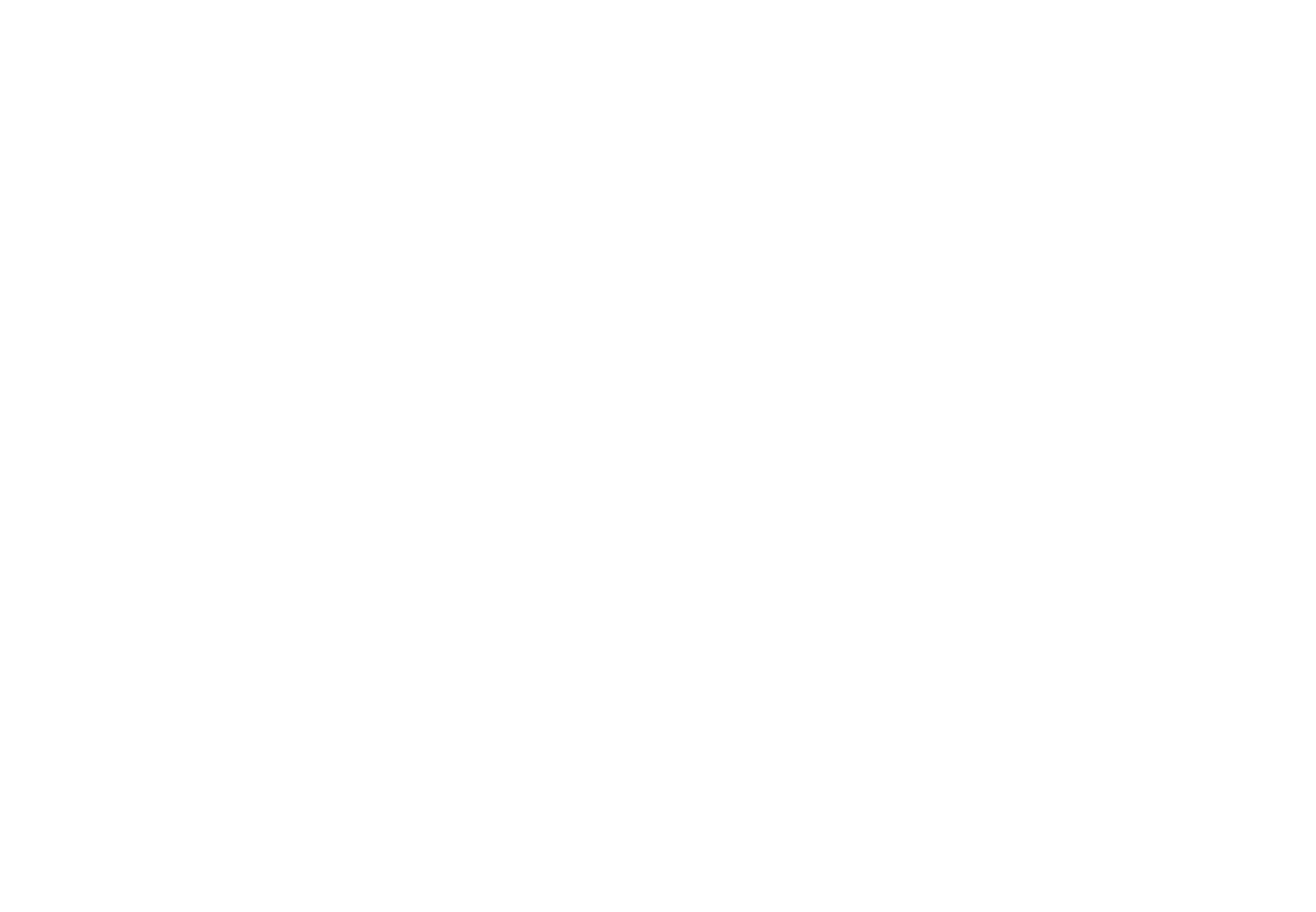

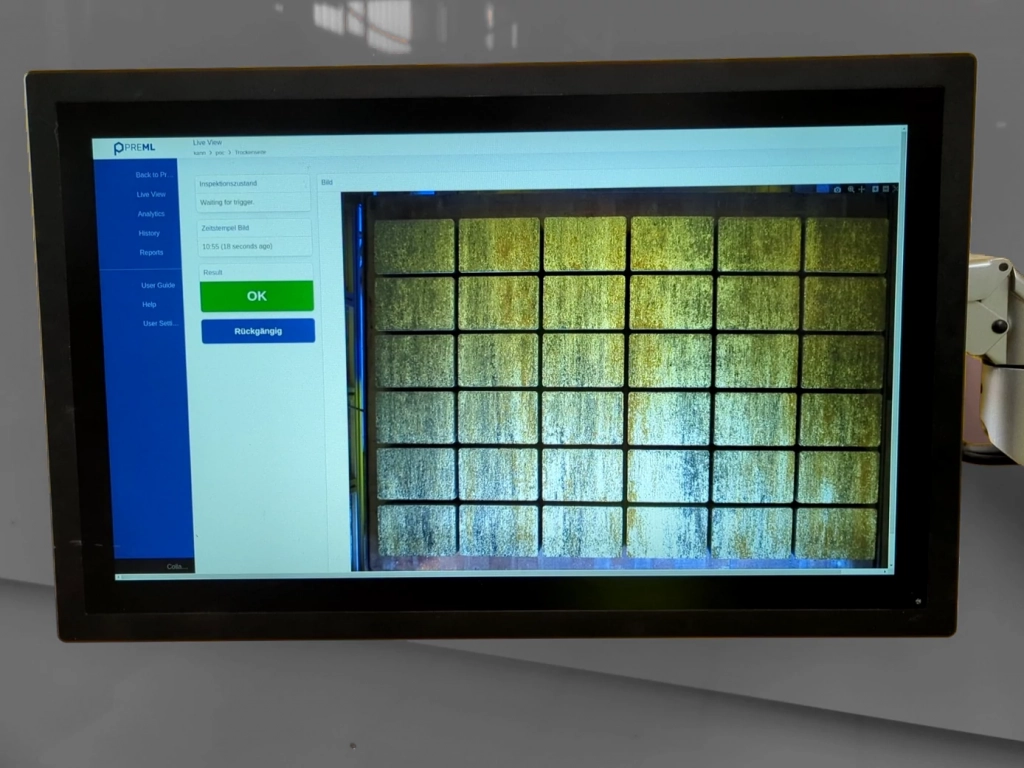

Anomaly Detection

Inspects: Everything visible on a image

Anomaly detection offers numerous benefits, including the ability to identify unknown defects and train models using only good images. This cost-effective solution is compatible with all products within the size range of 30 x 30 x 5 cm and is easy for anyone to install.

Aluminium Surface

Inspects: Aluminium parts (automotive)

For one of our automotive industry customers, we developed a system to reliably detect cracks in extruded aluminum surfaces. Since the inspected parts are critical components, the system must meet exceptionally high standards.

Surface Flatness Inspection

Inspects: Precast Concret Elements (wet side)

In one of the world’s most modern precast concrete production facilities in Switzerland, a robot smoothes the surface of the fresh concrete.

Our system is used to capture images with two 2D cameras and inspect the surface for holes or uneven areas.

Defect Detection in Concrete

Inspects: Small Concrete Products

In collaboration with our customer, we developed a system that detects defects such as cracks and spalling using 2D image data.

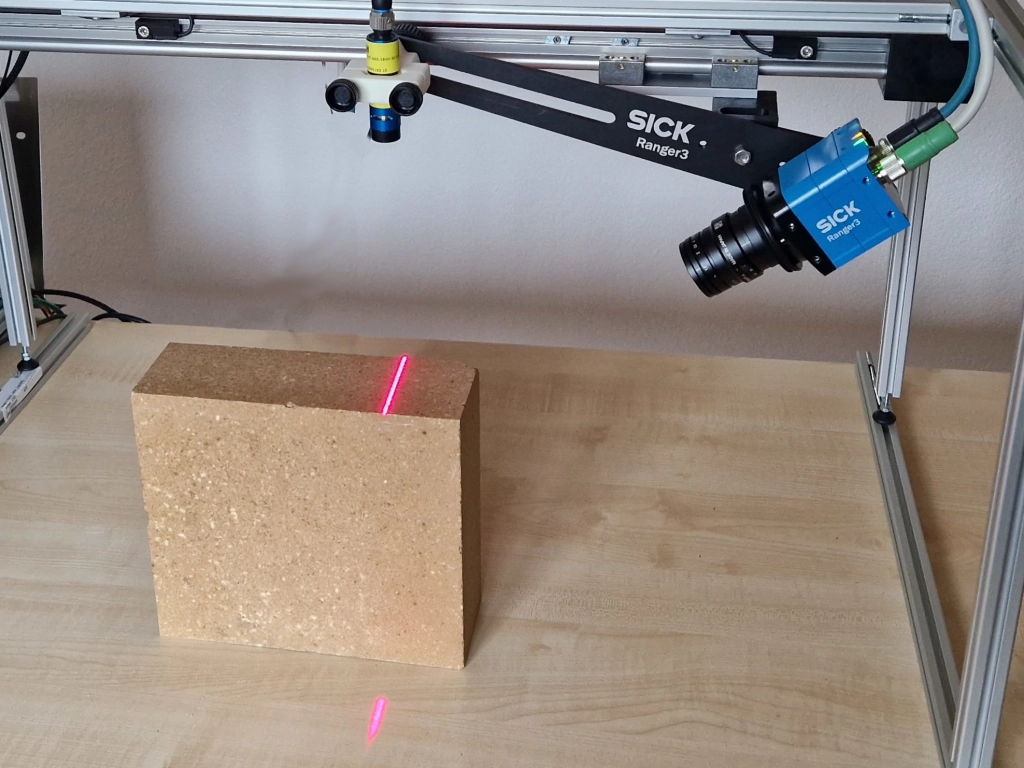

Digitization of the Measurement Process

Inspects: Railway Sleepers

This use case benefits from a combination of line scan cameras and 3D cameras to meet the high quality requirements in the production of railway sleepers.

Critical points of the product are the areas of the rail supports where sub-millimeter accuracy is required.

Real-Time AI Solutions

Inspects: Vehicle Detection, Load Estimation, and Drive Direction

We offer AI-based computer vision models that utilize image data extracted from video streams for real-time applications, such as logistics optimization.