Author

David Fehrenbach

David is Managing Director of preML and writes about technology and business-related topics in computer vision and machine learning.

Incomplete assembly sets at the customer’s premises are annoying and expensive. A system based on modern AI algorithms recognizes incomplete sets in real time. This ensures that no parts are missing when compiling individual parts into assembly sets. How does the solution work and how can it be used? Find out more in this text!

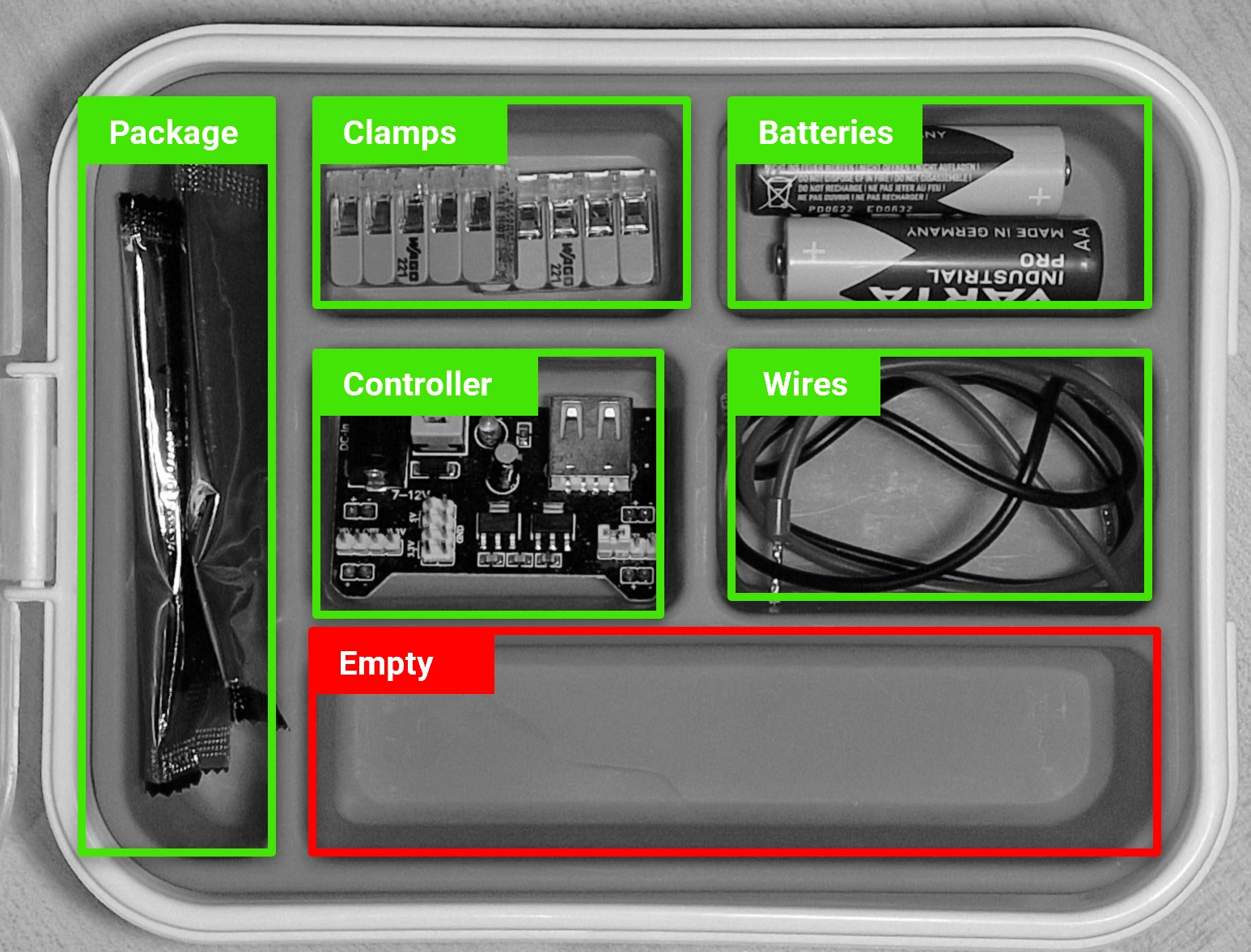

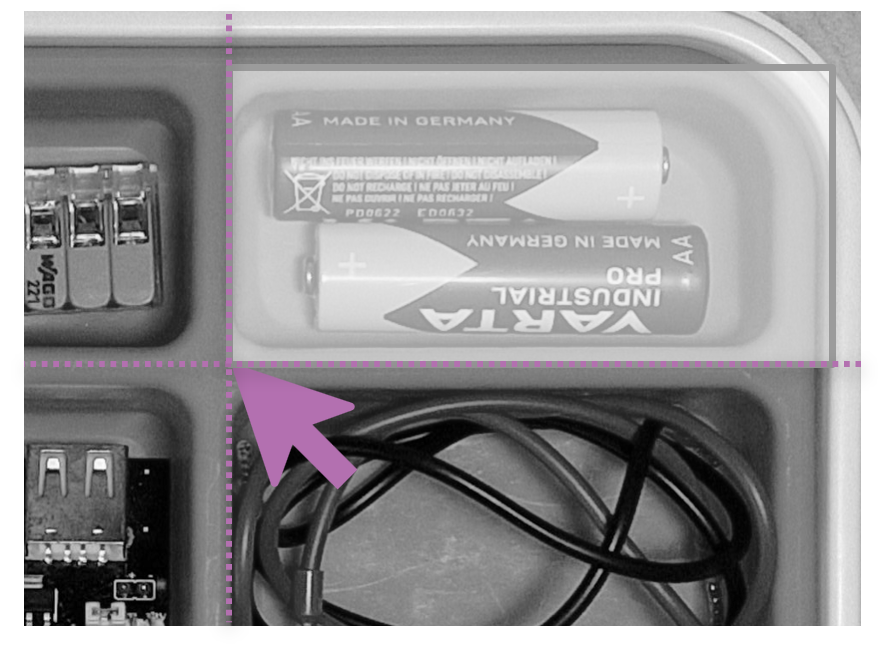

Figure 1: The colored annotation frames show the recognition of the objects in the recesses provided for them in green. Missing or incorrect objects are highlighted in red. (c) preML GmbH

Process integration

A camera is used to monitor the station and record all parts. Missing parts are displayed on a screen to inform the employee. Information can be transferred to the production and quality system.

Configure new positions

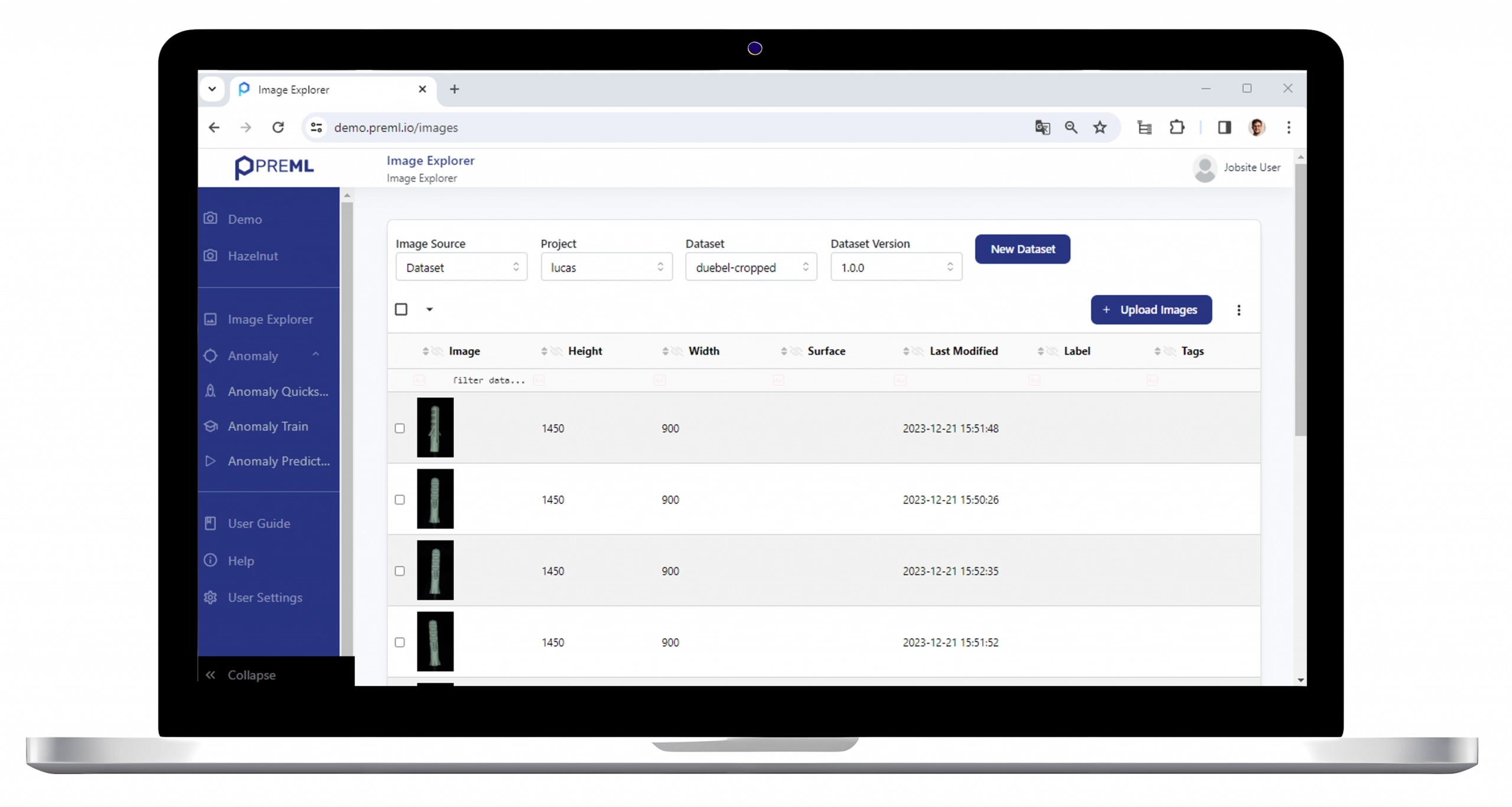

Simply mark and position the parts in the configurator using drag & drop. Interfaces with the system control automatically load the correct configuration for new orders.

Train the AI yourself

Through targeted annotations, the AI system continuously learns and adapts to your specific needs. Learn to recognize your parts yourself and improve the accuracy of the results with every interaction.

Sounds interesting? Feel free to contact us and receive a free feasibility check for your company!

We look forward to publishing more results of the project soon!

David

Feel free to contact us anytimes at contact@preml.io

Autor

David Fehrenbach

David is Managing Director of preML and writes about technology and business-related topics in computer vision and machine learning.